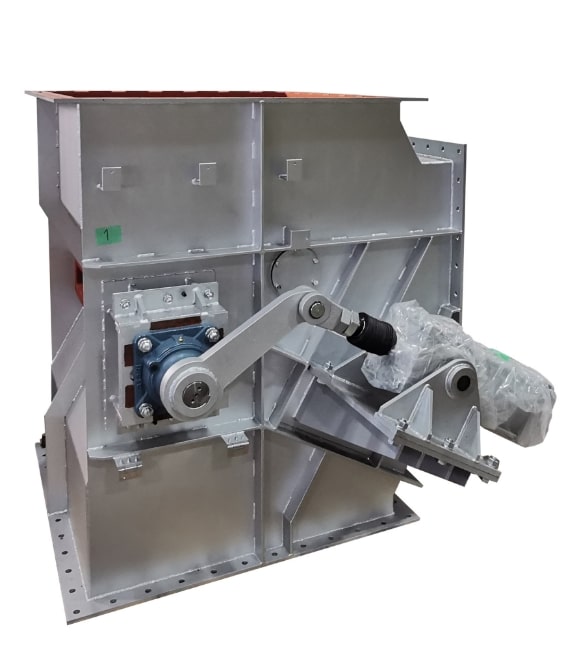

Integrated System from Design and Manufacturing to Quality Control and On-site Construction

SEC's design staff is responsible for designing the necessary equipment. Our production management staff and our own factory then work together to manufacture the product, and our quality control department checks its quality before shipping.

For on-site construction, SEC's construction staff handles everything from construction planning to on-site management. SEC's technical expertise is fully utilized from design to on-site construction.

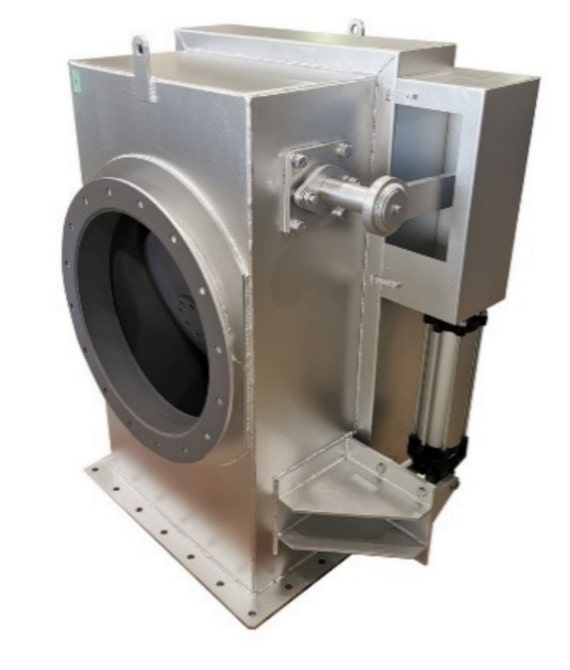

Device Control and Electrical Construction

Equipment must operate safely, accurately, and be easy to use. To achieve this, proper planning of electrical and instrumentation equipment is essential. SEC offers comprehensive support, from formulating operation plans, electrical and instrumentation equipment configurations, and control and power panel specifications to planning and managing installation and electrical wiring work, to proposing safe, accurate, and easy-to-use equipment.

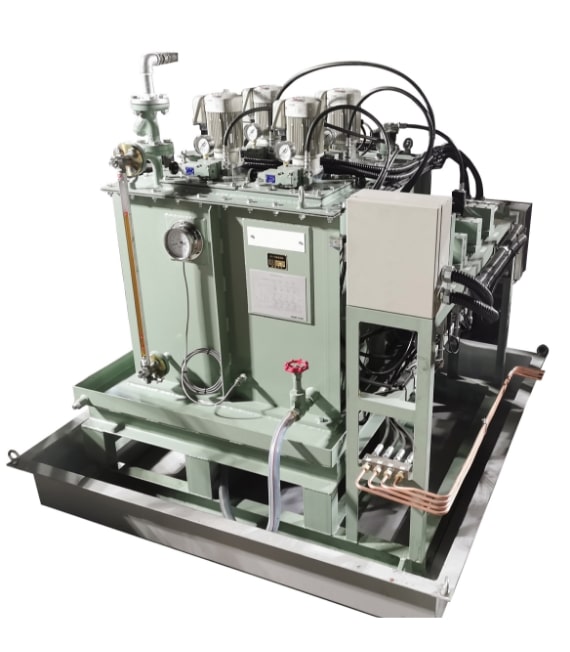

Proposal Sales

Whether your requirements are clear or not, SEC staff will listen to your requests and issues and assist you from the specification formulation stage.

Not only sales staff, but also design, manufacturing, and construction staff will be present as needed, to create the equipment together with you.