In the 20th century, the world competed to advance technology and build a wonderful society,

but at the same time,

it created the major problem of environmental pollution.

The Irony is that technology that was supposed to enrich our lives has instead

polluted the environment and made our society more difficult to live in.

The SEC Group is pursuing technologies that protect the global environment.

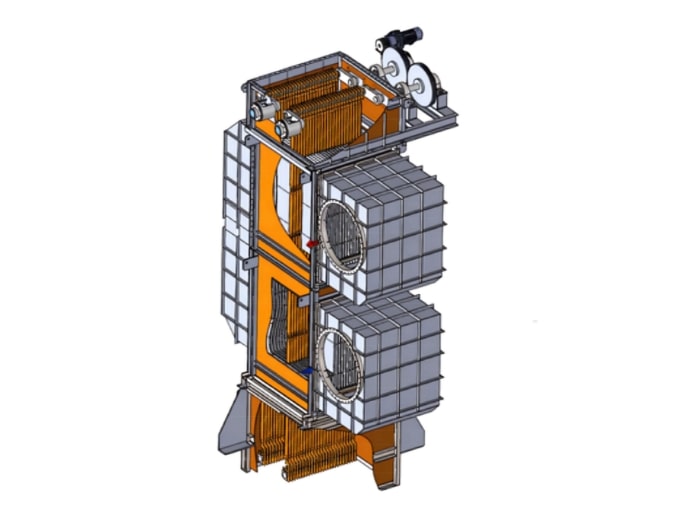

Technology that reduces CO2 emissions,

treats harmful exhaust gases,

and recycles waste instead of incineration.

Our environmental protection technology is indispensable

for the world's pursuit

of greater prosperity.

The SEC Group is engaged in a wide range of businesses, including flue gas treatment equipment for waste incineration plants and steel mills, various conveying equipment for recycling facilities, and the design, manufacture, and sale of electronic circuit board material manufacturing lines.

Since our founding in 1978, Sanwa Engineering has continued to focus on manufacturing with the support of our customers.We strive to nurture our technology and people, and to remain the best partner for our customers. We are constantly striving for growth and a positive outlook.