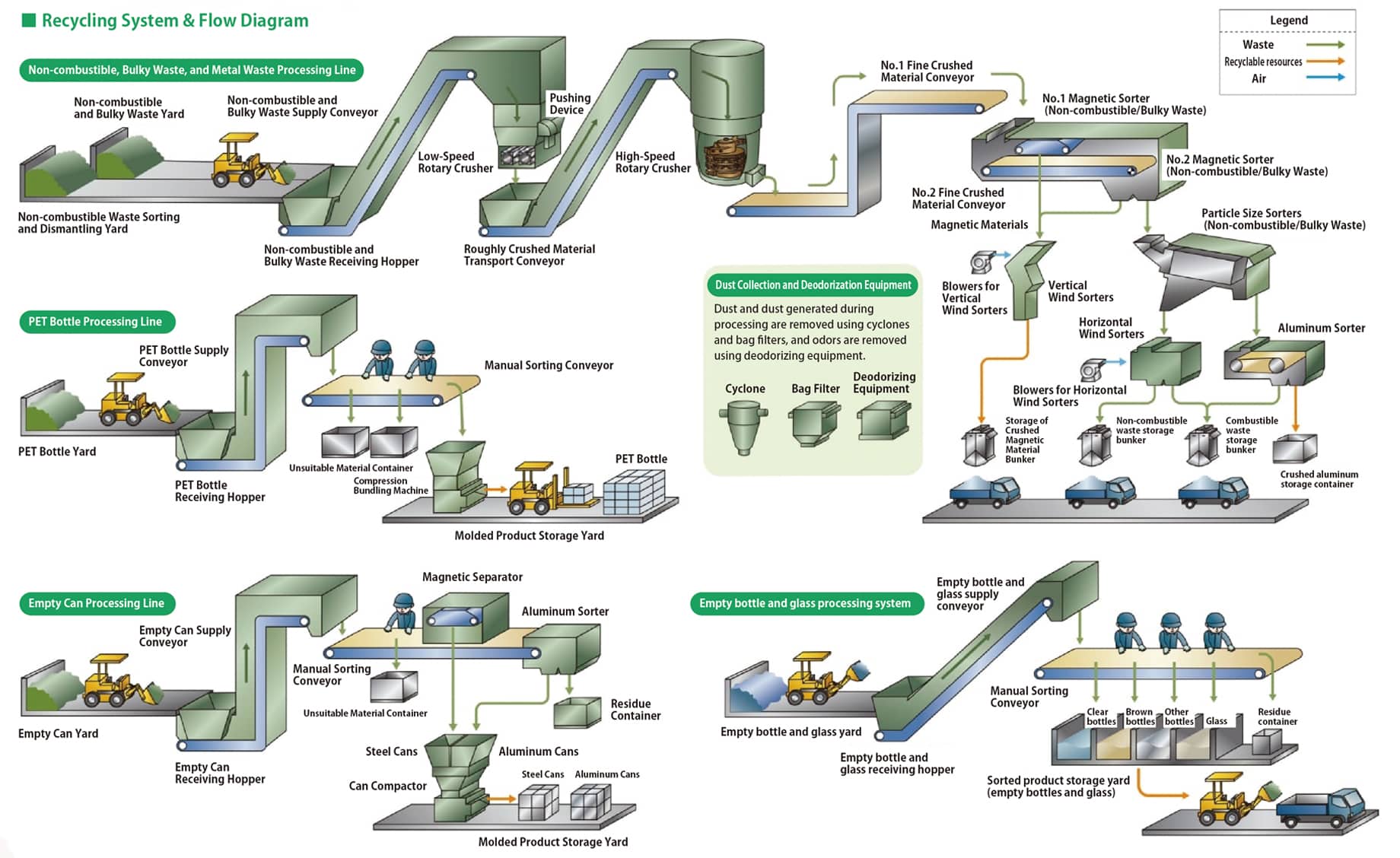

Material recycling centers are facilities that efficiently crush and sort bulky waste and recyclable materials disposed of as general waste by municipalities.

In recent years, growing public interest in environmental issues and the establishment of various laws have led to increased efforts to recycle used materials such as aluminum, steel, PET bottles, and plastics.

As a result, the role of recycling centers continues to grow in importance.

Our recycling center meets growing societal needs and contributes to the realization of a "circular economy."