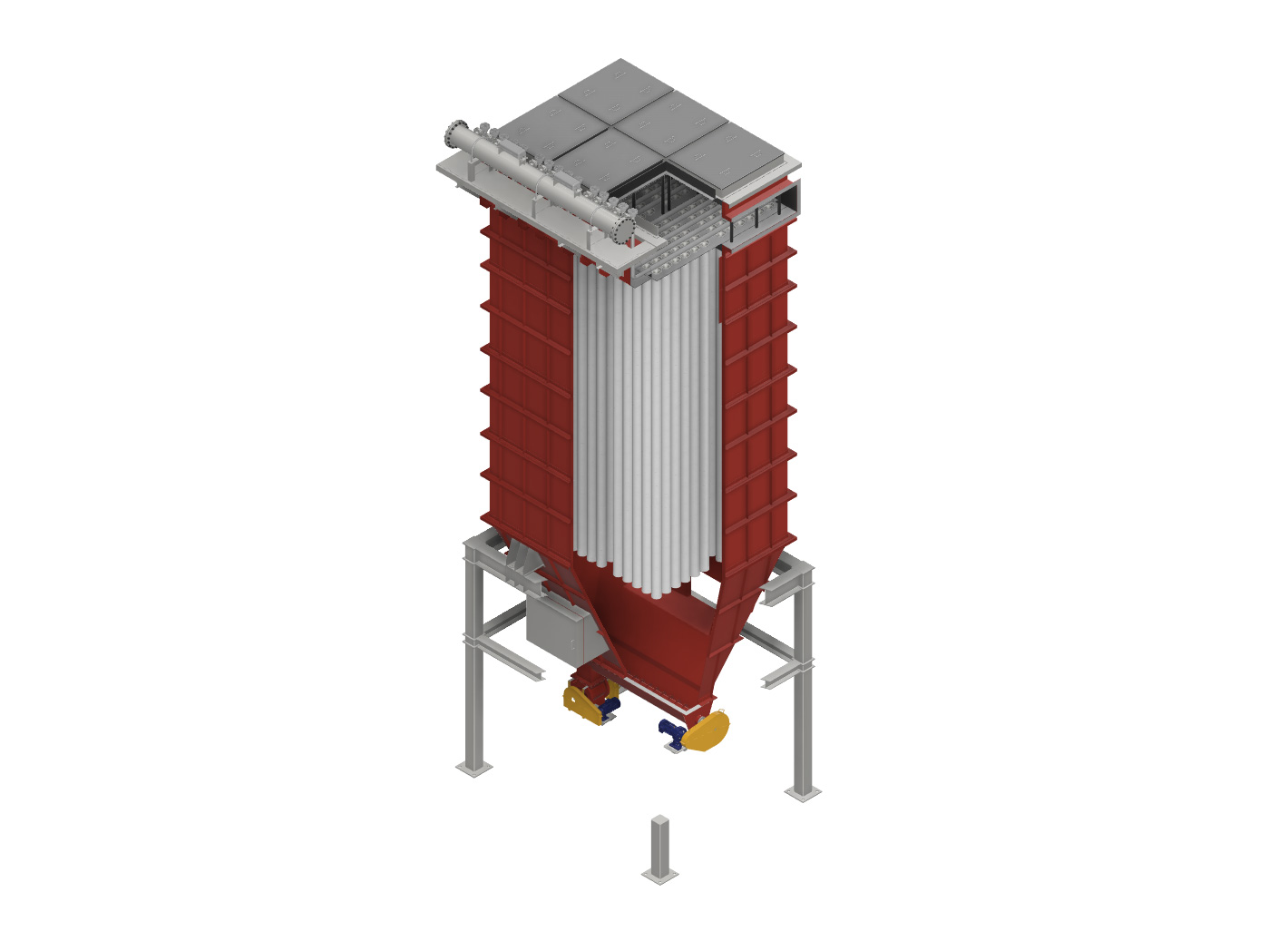

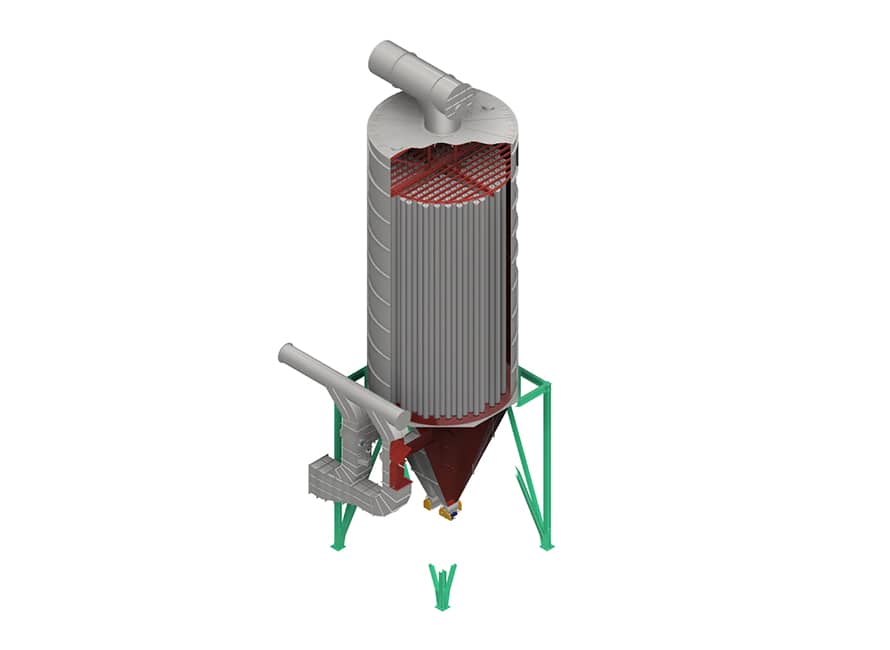

In bag filters, as the dust layer collected on the filter cloth thickens, pressure loss of the filter element increases, making it difficult to maintain pressure inside the incinerator.

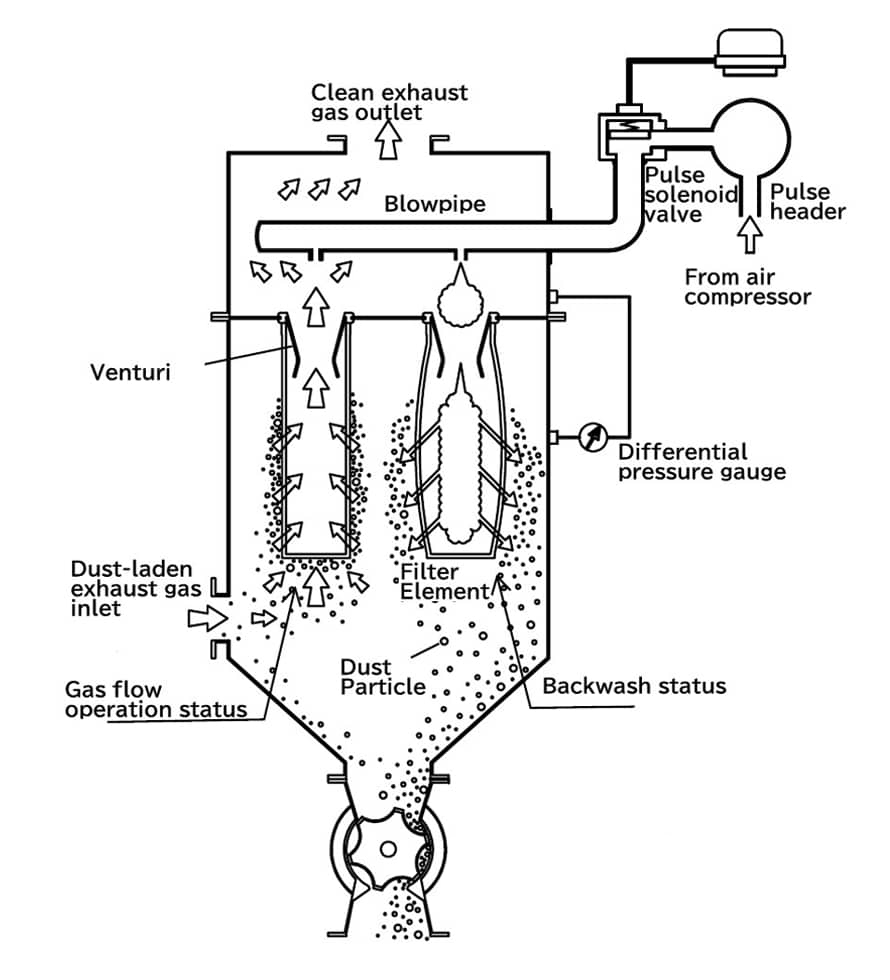

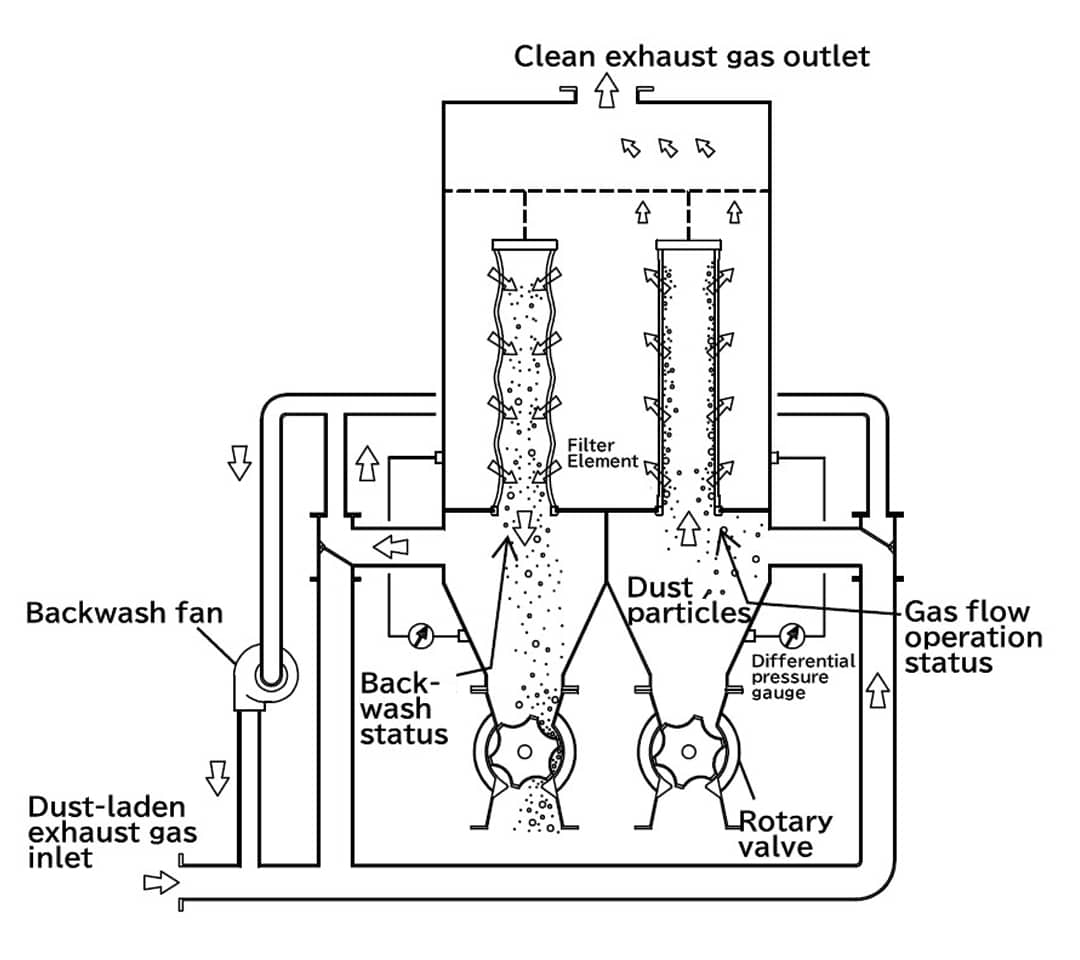

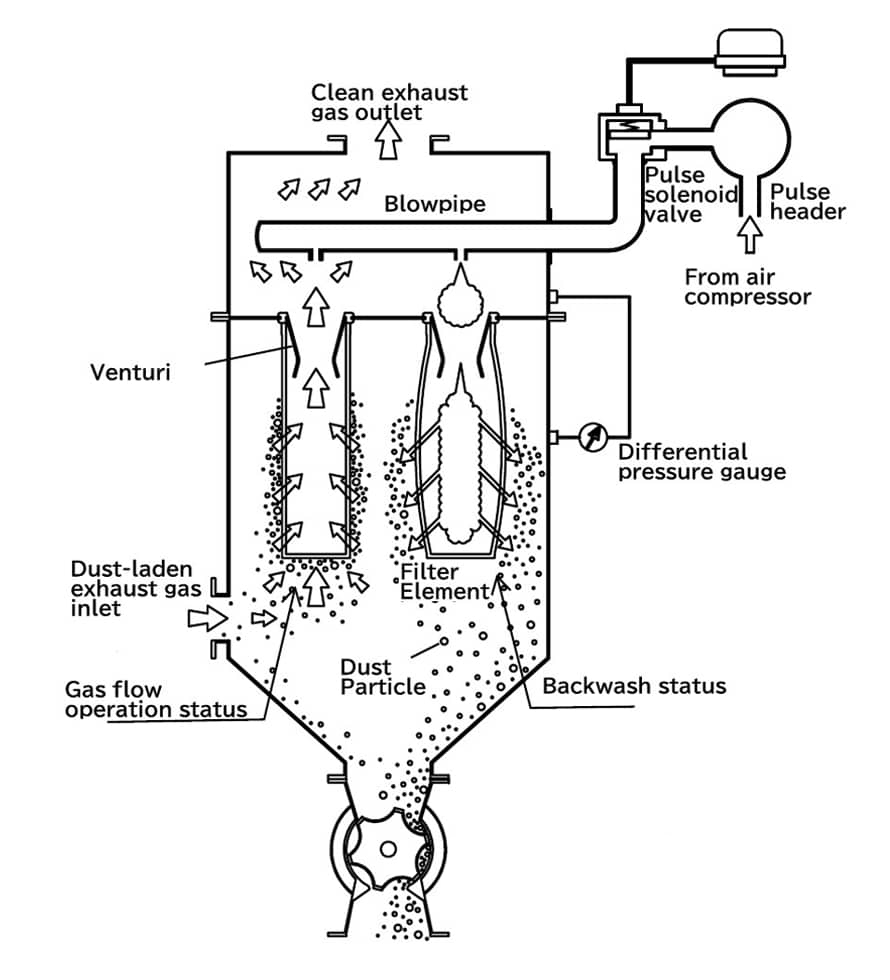

For this reason, we use a pulse jet system to periodically blow dust off the filter cloth.

The blowpipe (backwashing system piping) installed above the filter cloth is connected to a pulse header installed in the ceiling of the bag filter via a pulse solenoid valve (diaphragm valve).

By periodically opening and closing this pulse solenoid valve, compressed air from the pulse header flows into the blowpipe and is injected into the venturi through the blowpipe nozzle.

The injected compressed air draws in several times the amount of secondary air from the surrounding area due to the Venturi effect, causing the air to flow in the opposite direction to normal filtration, expanding and backwashing the filter cloth and removing dust adhering to its outer surface.

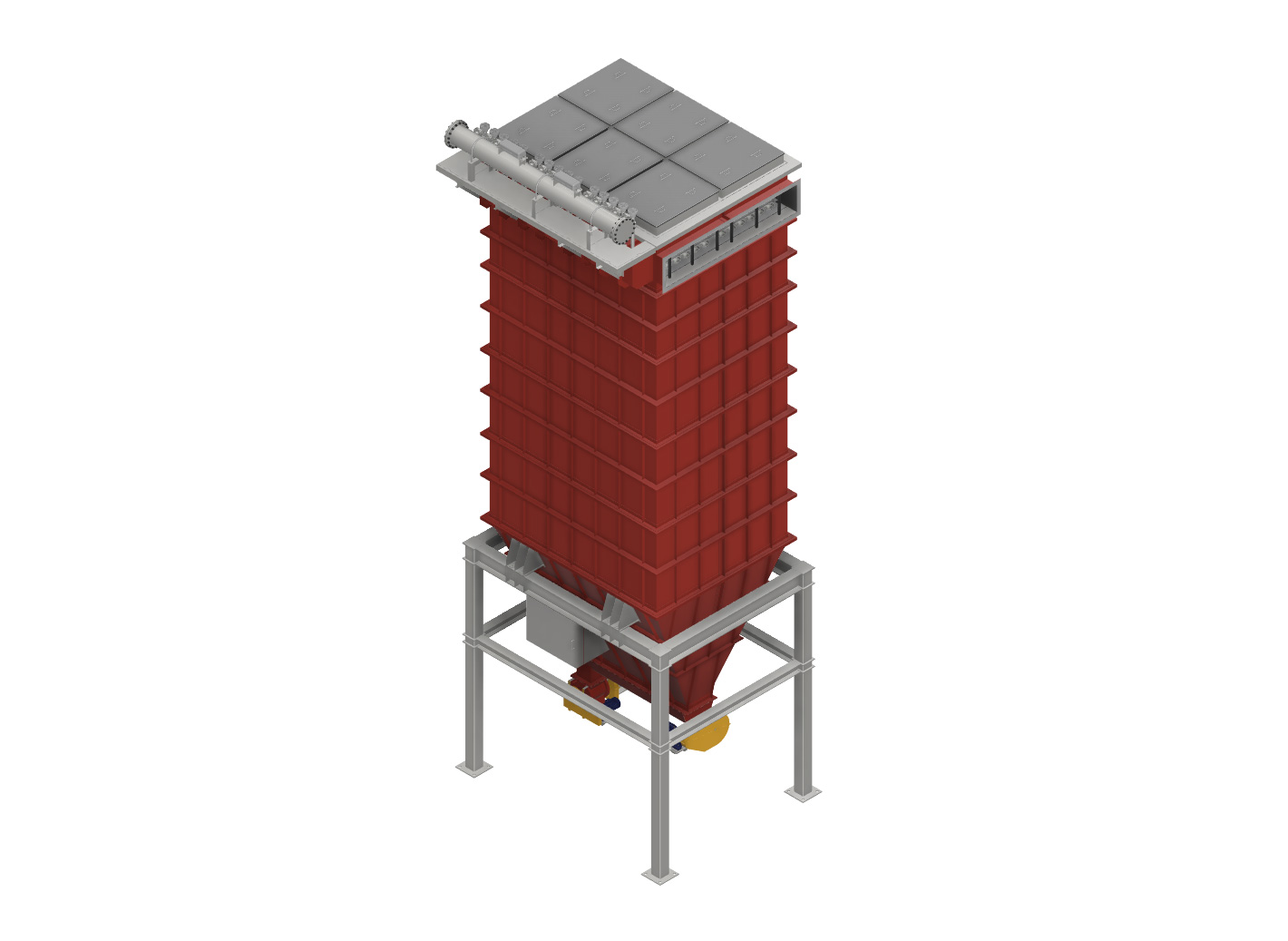

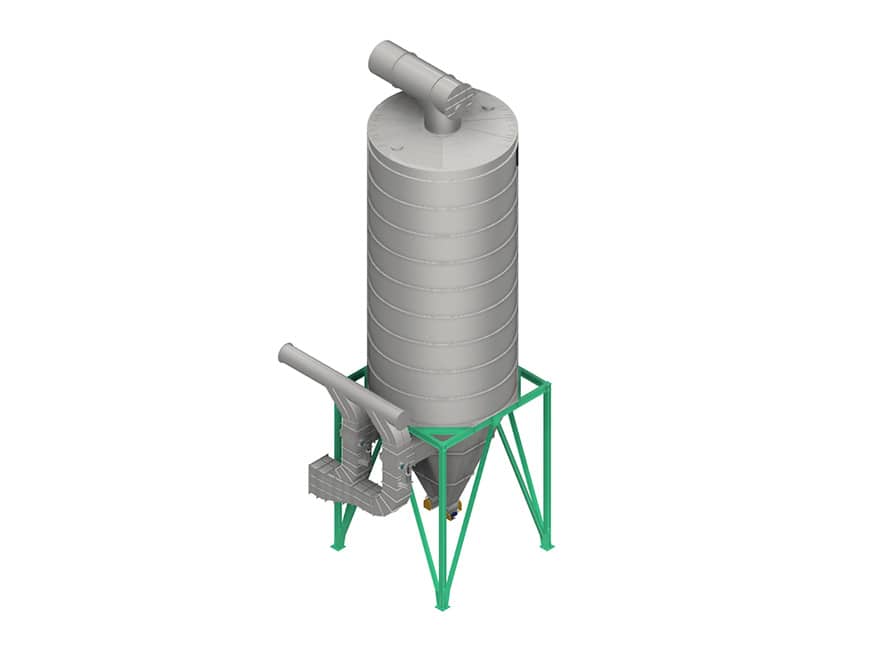

Leveraging our track record of approximately 200 deliveries, we design and manufacture compact, low-cost bag filters.

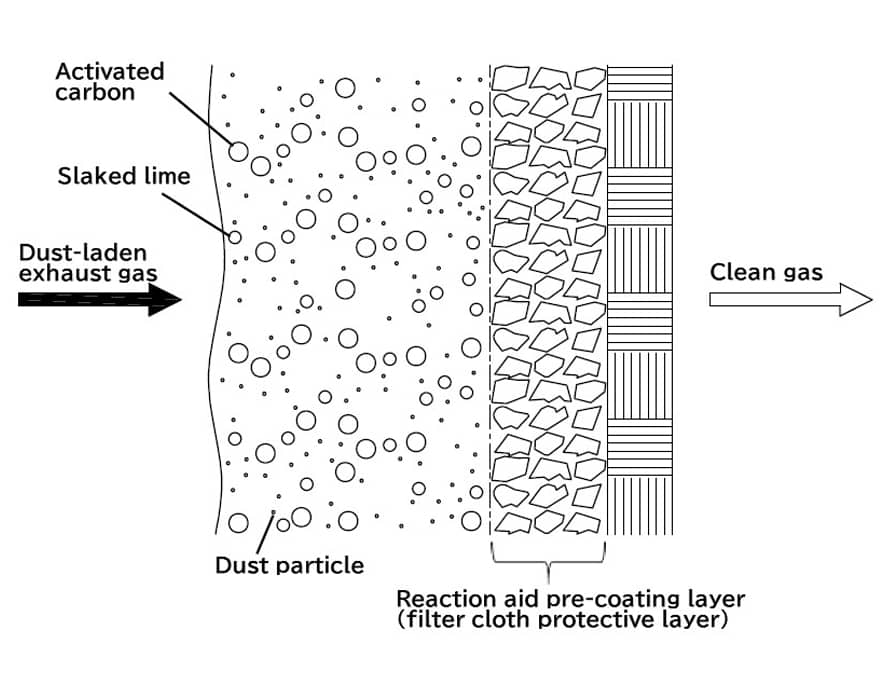

The key to removing impurities from exhaust gas in a bag filter is the filter cloth.

The filter cloth consists of multiple layers, and the surface that comes into direct contact with the exhaust gas accumulates not only the adsorbed particulate matter, but also the injected catalyst (such as hydrated lime or activated carbon) and reaction products created when the particulate matter reacts with the catalyst.

The neutralization reaction between the catalyst and the harmful substances contained in the particulate matter takes place in this deposition layer.

Furthermore, as the sediment layer thickens, the pressure exerted on the exhaust gas as it passes through the filter cloth increases (increasing pressure loss).

When this pressure exceeds a certain level, the filter cloth cannot withstand the pressure and is prone to tearing or damage. To prevent this, baghouses are equipped with a mechanism to brush away the accumulated dust and other particles from the filter cloth.