Our company designs, manufactures, delivers, and installs heat exchangers, primarily for waste incineration facilities.

Heat exchangers are equipment used to recover thermal energy from the high-temperature exhaust gases generated by waste incineration.

Reusing the thermal energy generated during waste incineration is called "thermal recycling," and heat exchangers are devices that carry out this process.

The thermal energy recovered by heat exchangers is used for a variety of purposes, including supplying hot water to the surrounding area, reusing it as air for waste combustion, and preventing white smoke when exhaust gas is released after treatment.

Leveraging our extensive delivery track record and technical capabilities, our heat exchangers continue to boldly take on environmental issues.

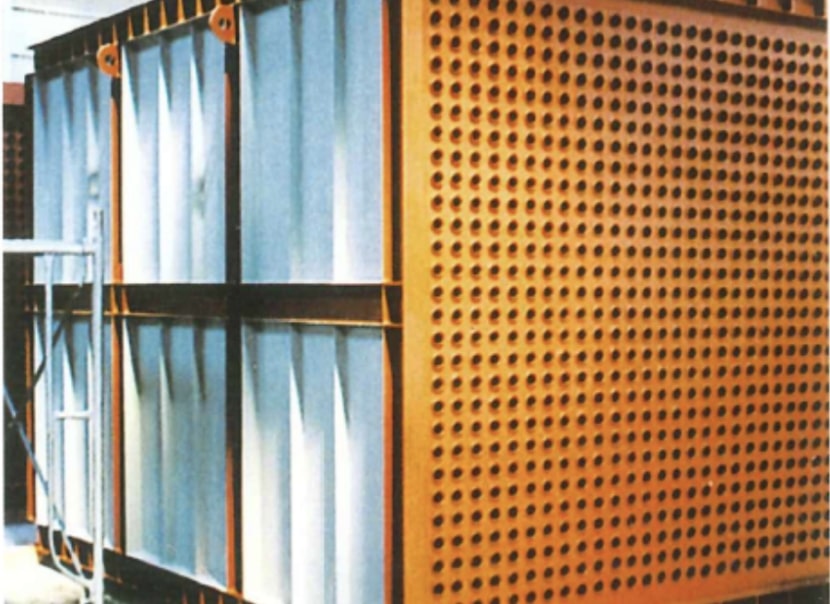

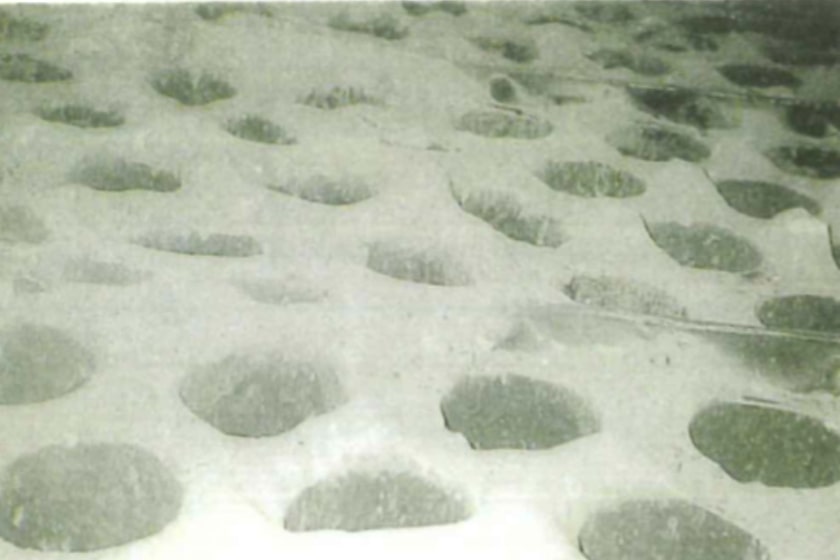

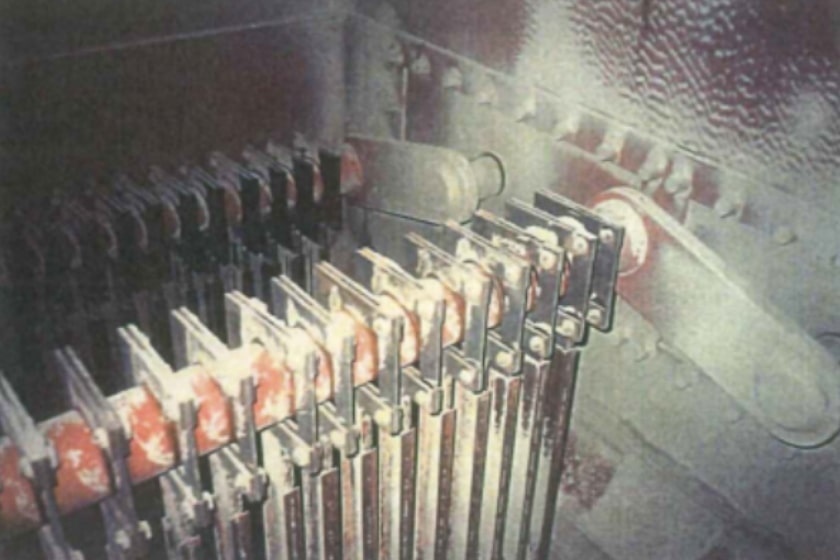

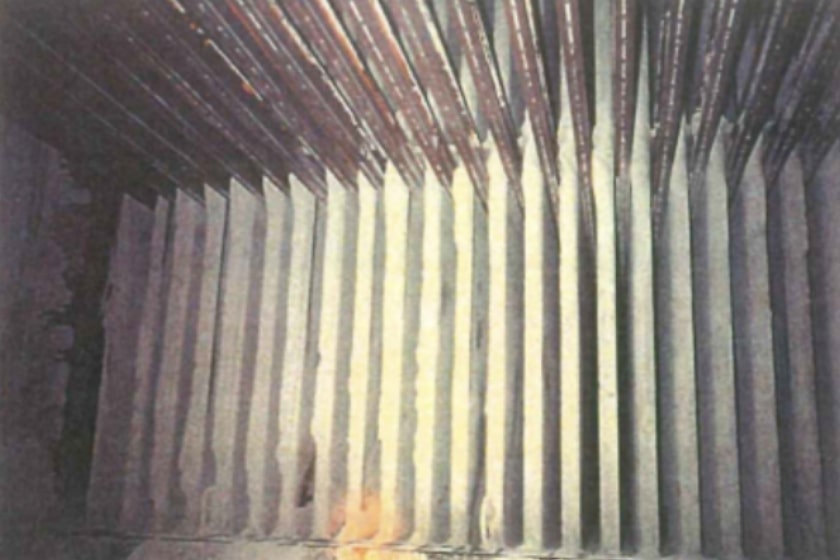

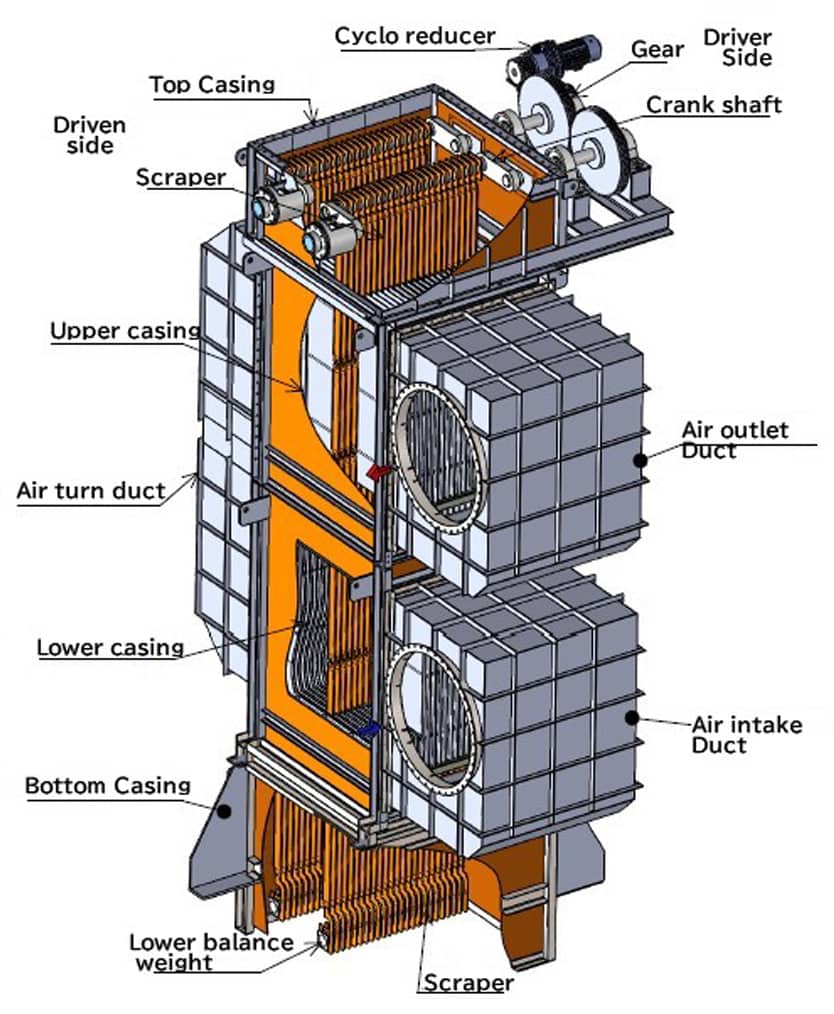

The diagram above shows the internal structure of a plate heat exchanger. The scraper attached to the crankshaft oscillates to prevent dust from adhering.